INCENSE PRODUCTION PROCESS

STICK INCENSE PRODUCTION PROCESS

1.Measuring and Mixing

A Large variety of powdered aromatic wood, herbs and spices is measured accurately and mixed according to the type of incense. The powders are sifted to mix evenly and remove particles.

2.Kneading

Measured amounts of sifted powders are kneaded gradually with the addition of warm water and mineral colors.

3.Pressing

Kneaded material is pressed into cylindrically shaped.

4.Extruding and Cutting

A hydraulic extruding machine compresses the cylindrical "dough" through the small holes of the steel mold, called "Sugane," into the form of long strands similar to a spaghetti noodle. A board, called "Bon-ita" catches the soft strands of incense. Both ends of the stick incense are trimmed by hand with a bamboo knife.

5.Arrangement

Soft incense is removed from the Bon-ita and put onto another wooden board, called a "Tehon-ita", and laid very closely next to each other.

6.Adjustment

Cut the end of any incense that sticks off of the Tehon-ita to make it even. Move again, to another board to dry. At this point, some of them are cut further to meet product specifications.

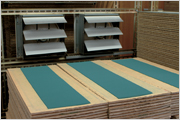

7.Drying

The drying boards are piled up with a little space between them. Incense is dried slowly in a few days.

8.Finish

The dried incense sticks are weighed and bundled in the appropriate quantity for the final packaging.